What does soil texture have to do with manure? Sand bedding has become a popular choice at many dairies due to the cow comfort and health benefits it offers. A question raised at manure application time is how does sand in the manure impact the health of my soils? While using sand laden manure as a fertilizer source does add sand to the soil, the change is small and would take about 100 years for a silt loam soil to see a change in soil texture.

What is soil texture?

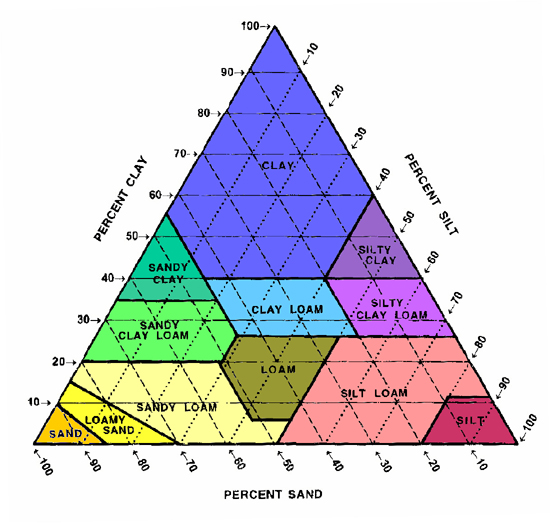

Soil texture is the relative proportion of sand, silt, and clay sized particles in a soil. Properties associated with soil can be partially explained by knowing soil textural class. For example, when you hear sandy soil you instantly think low water holding capacity, water moves quickly through it, and nitrogen will be susceptible to leaching. Clay soils tend to be the most important in determining the soil properties. This can be seen by examining the soil triangle as only about 25% of the soil needs to be clay to have “clay” included in the soils name, where as it takes 40-50% of the soil to have silt or sand included in the name (figure 1).

How much soil?

The first thing we need to know is how much soil is in an acre. To make this calculation, we are going to measure four inches deep, as most tillage equipment would work to this depth. Assuming a soil density of around 75 lb/ft3 we’d have about 540 tons of soil in an acre.

How much sand?

The next question is how much sand are we using per cow? A typical estimate is around 50 pounds per cow per day, or about nine tons a year. That same cow is estimated to excrete about 160 lb P2O5 per year (ASABE Manure Production and Characteristics, 2005). Assuming we don’t separate and recover any of that sand, for every pound of P2O5 we add to the soil we’d be adding 112 pounds of sand (assuming we are getting the sand evenly mixed with the manure). Additionally, you’ll be adding about 10 pounds of organic carbon to the soil for every pound of P2O5, with most estimates indicating that this will result in 1 pound of stabilized organic carbon in the soil (Maillard and Angers, 2014). However, most dairies will use some sort of sand recovery, perhaps sand settling lanes (50-70% of the solids captured), weeping walls (50-85% of solids captured), or mechanical sand separators (50-95% of solids captured). Assuming sand recovery of 50%, we’d be down to about 60 lbs of sand per pound of P2O5.

How much manure?

The next question becomes how much manure are we going to put on and how often. Although it’s hard to pick a typical manure application rate, if we wanted approximately two-years’ worth of P2O5 in a corn-soybean rotation (135 lb P2O5/acre*), and assume a 50% sand recovery rate, we’d be applying about four tons of sand every other year (or equivalently two tons every year). Let’s say our soil was a loam (20% clay, 40% silt, 40% sand). This means right now my soil has 108 tons of clay, 216 tons of silt, and 216 tons of sand in an acre. If I added two tons of sand, my soil texture would change to 19.9% clay, 39.9% silt, and 40.2% sand; an imperceptible change. However, keep doing this for 84 years, and your soil texture would be 15% clay, 29% silt, and 56% sand – a sand loam soil.

Does it matter?

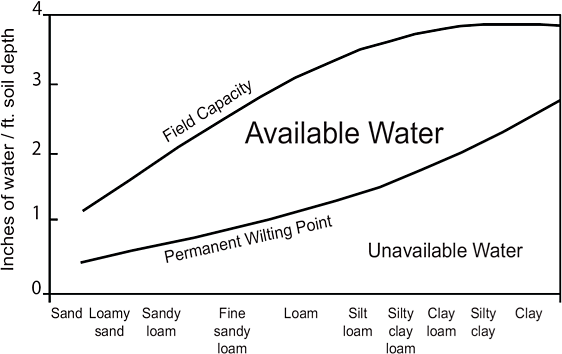

Is the soil better or worse than it was before? The impact this has really depends on what our original soil texture was, the effect of the nutrients you add, as well as the added carbon. However, here we will focus on just the impact of the sand. As shown in figure 3, if we start with clay soils the addition of sand will increase the available water capacity of the soil, if we start with a loam soil it will decrease it. Similarly, as soils get sandier we will generally increase the soil’s hydraulic conductivity and infiltration rate.

*Assumes 220 bushel corn with 0.37 lb P2O5/bu followed by 65 bushel soybean at 0.8 lb P2O5/bu.

Authors: Dan Anderson, Iowa State University

Reviewer: Rick Koelsch, University of Nebraska – Lincoln

Funding support from North Central Region Water Network.